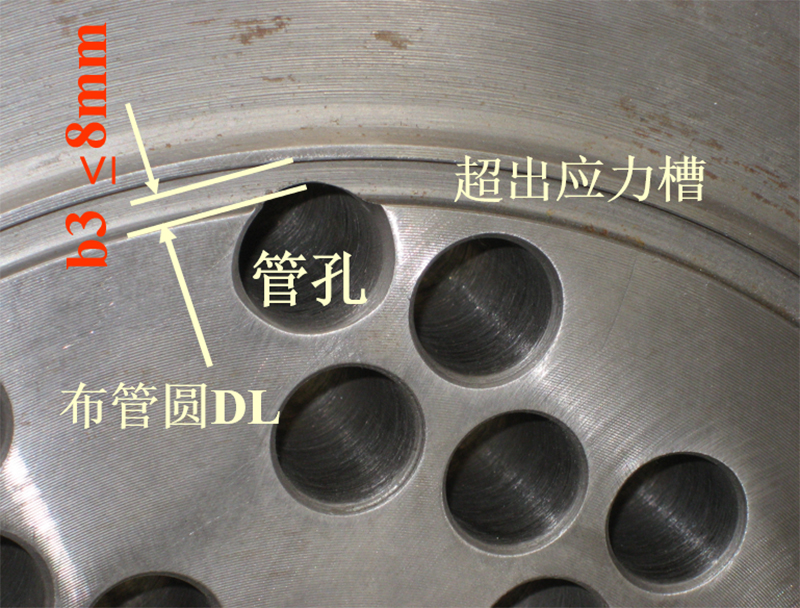

1. The pipe hole is opened on the stress relief groove

In a certain project, the designer drew the heat exchanger and produced a separate drawing of the tube plate, which was then sent to the workshop for manufacturing.

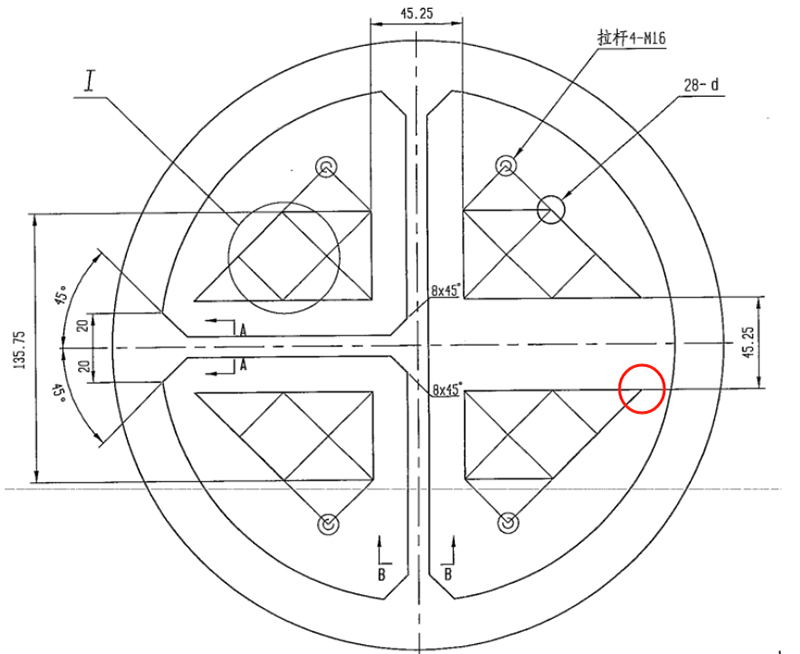

After the completion of the tube plate processing, it was found that four tube holes were opened on the stress relief groove.

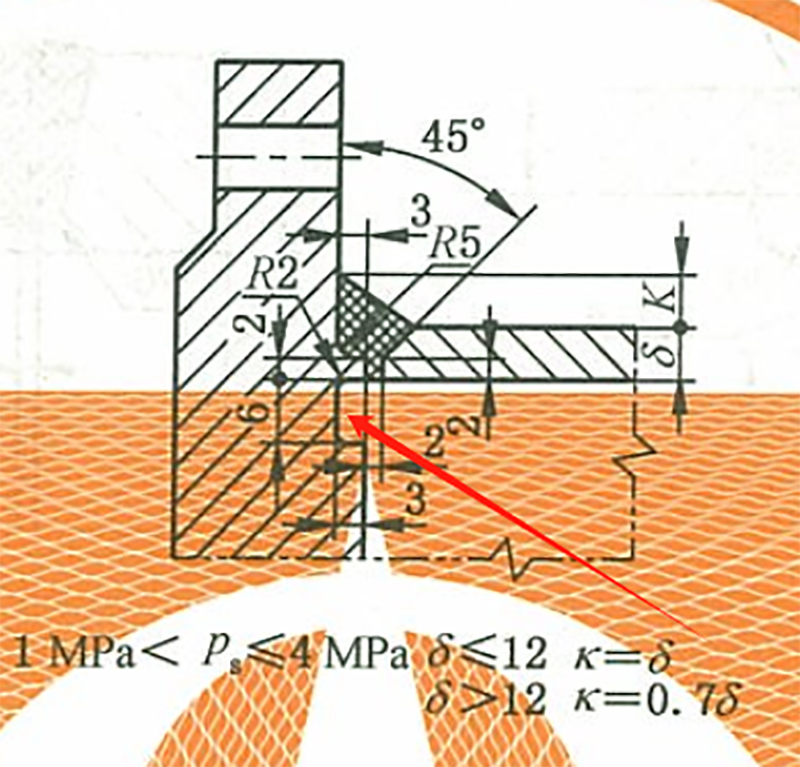

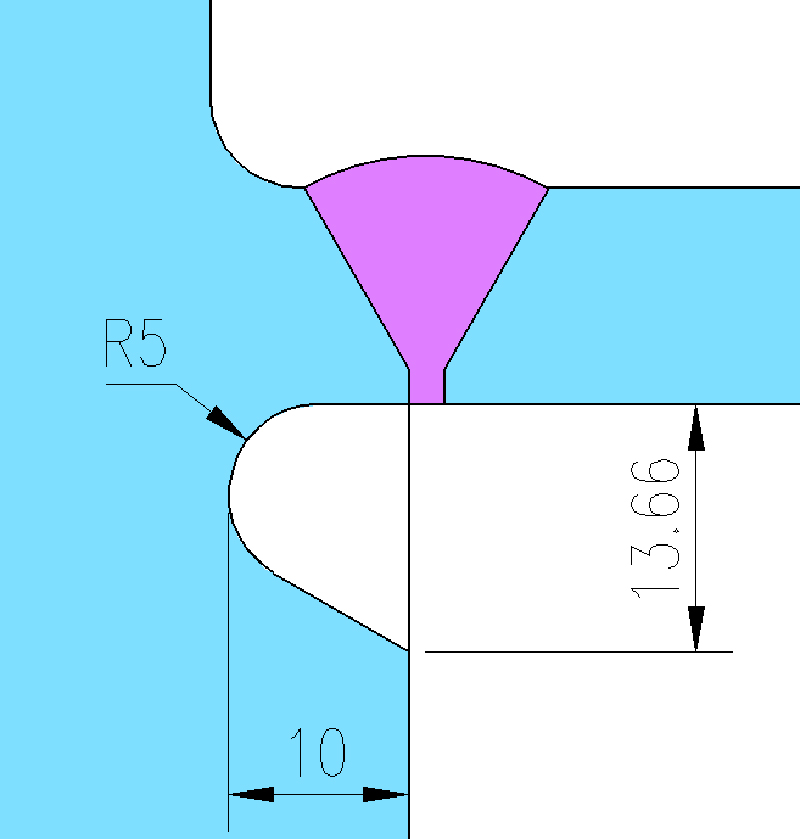

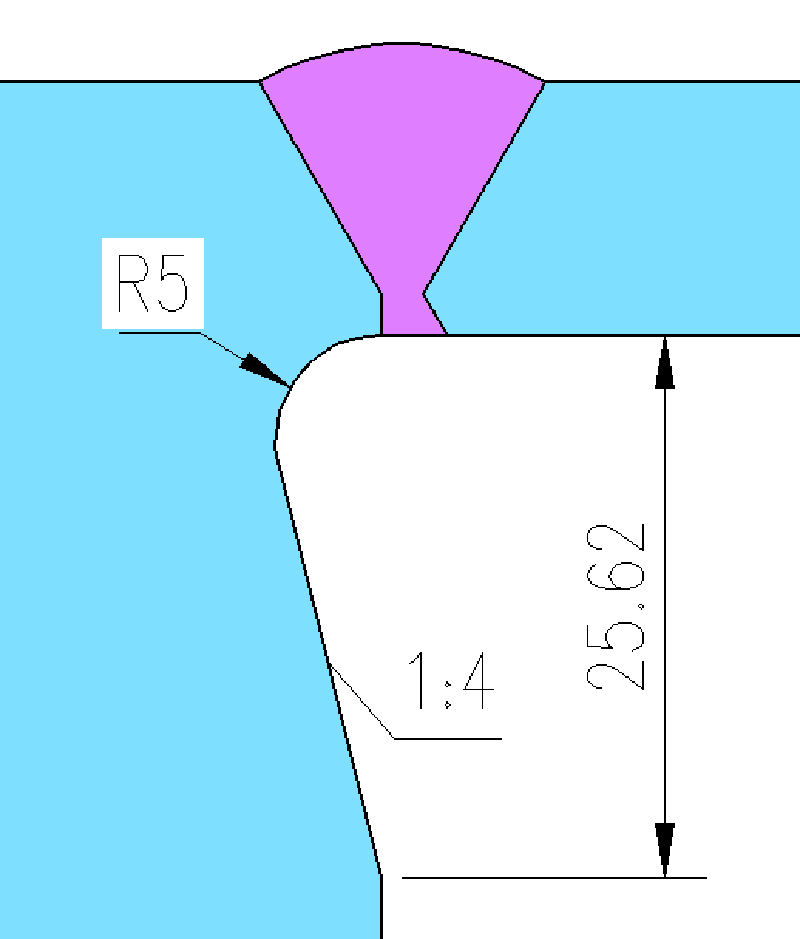

The structure used for the tube plate is:

Check the reason, it's becauseLimit the circle of the pipeNot considered.

When creating the canvas tube diagram, only the inner diameter of the cylinder was considered,Not drawing the pressure relief grooveAnd the drawing of heat exchange tubes adopts a method similar toThe method of drawing only the centerline。

RegardingThe distance between the edge heat exchange tube and the confined circleIt is difficult to perceive intuitively.

2. Consideration of limiting the circle for pipe laying in the s

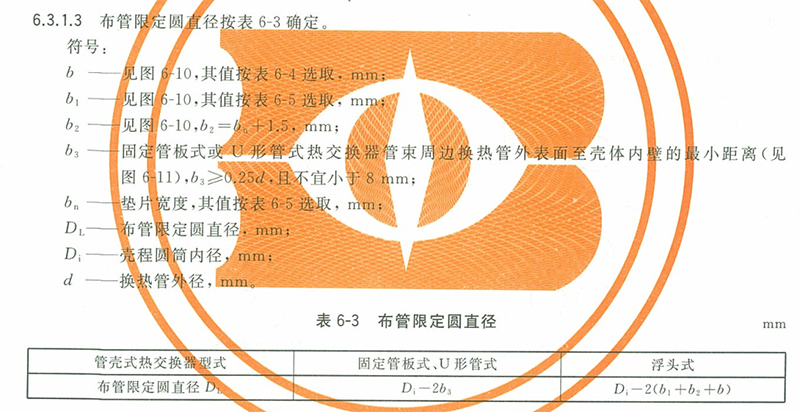

In section 6.3.1.3 of GB/T 151-2014, there are detailed regulations on the diameter limit for pipe laying circles.

The limited circle diameter for fixed tube plates and U-shaped tube platesDL=Di-2*b3, b3>=0.25dandNot less than 8mm。

After measurement, the distance b3 this time is basically around 4mm, less than 8mm.

If it can be executed according to the maximum limit circle diameter of GB/T151, it is impossible to open on the limit circle.

3. Solution

The wooden boat is already done, and the manufacturer certainly hopes to make concessions and accept the issue of pipe boards.

Otherwise, they will face:

1. The entire stainless steel heat exchanger needs to be redesigned and its strength recalculated.

2.If it is necessary to increase the diameter to meet the process requirements, it means that all processed components such as the cylinder, pipe box, and equipment flange are scrapped, and the cost is too high.

3. If deleting 4 heat exchange tubes is acceptable (reducing heat exchange efficiency by 8%), then there will also be a lot of trouble in procuring and processing materials for the tube plates.

In order to reassure homeowners, manufacturers have found many reasons:

For example, it is not mandatory to limit the circle for pipe laying ..

For example, there is no evidence to suggest that opening it in a pressure relief groove poses any harm ..

For example, because it is a strength welding, it doesn't matter if the pressure relief groove is opened ..

For example, TEMA does not have a restricted circle for piping, and GB151 copied TEMA

And promise to increase the warranty by 1 year. In the future, if there are any equipment quality problems due to opening in the pressure relief groove, a new one will be replaced free of charge ..

As long as it's not scrapped, let me argue a bit.

Stealing books can't be considered stealing... stealing books!... can the affairs of a scholar be considered stealing

-Kong Yiji

In the end, based on various considerations, the owner still accepted the concession.

4. Limit the circle of the pipe

The limitation of the circle for pipe layout generally has nothing to do with strength calculation, but it is important to avoid mutual interference.

For example, in GB/T 151, the minimum circle limit for the layout of fixed tube sheets isID-16mm。

But for Appendix I of GB/T151I. Type 1 (d) structure, 16mm is often not enough, it is generally necessary28mm。

And forI. Node (c) of 2,The single-sided distance of the stress relief groove is 26, and the pipe layout is generally limited to a circleInner diameter -52mm。

In this situation, it is necessary to carefully calculate whether the area of pipeline layout is feasible.

In addition, drawing the outer diameter of the heat exchange tube at the edge on the piping diagram is very helpful for visually observing whether it interferes with the defined circle.

COPYRIGHT © 2025 Zhejiang Mingfeng Pipeline Equipment Co., Ltd

Enterprise information service provider:JCSW